Products & Services

HOME / PRODUCTS & SERVICES

What we do

Try our Pit Builder to see your customised pit options

Other Products

Motorised Safety Cover

Driven by electric motors, a fully adjustable, retractable aluminium cover to give personnel protection. Fitted with safety alarms, lights and emergency stop sensor.

Budget Safety Cover

Manual pull fall restraint offering part or full closure option. Yellow in colour for maximum awareness.

Safety Barrier Ball Type

Permanent ball type handrail for bay separation. Gates can be fitted into long run installations. Other types of barriers include chains and flags.

Retractable Safety Barrier

Available in 12m, 14m and 16m lengths. Posts and recoils are supplied to provide a very cost effective pit barrier, they are highly visible and easily relocated.

Electrical sockets

Available in either 110V or 24V. Flame proof (Max 16A) Transformer by others.

Rail & Step Up Platforms

50mm x 50mm rail 200mm above pit floor level and 400mm high, 800 x 500mm Platform slides along the rail providing two different height gains

Pit Bridge

Manufactured from aluminium and can be provided with or without handrails providing a safe crossing on any pit, 1m.

Full or half width steps

All steps are manufacture with anti slip Elefant Tread. Half width steps are a cost effective storage solution.

Premier Jack

20 Tonne Pit Jack, air operated with twin rams. This jack comes with a 5 years’ manufacturer’s warranty.

Jacking Beam Store

Gives a clear working area down the full length of the pit by making it possible to position the jacking beam beyond the steps.

Pit Guide Rail

Guide rail for airport trains.

During pit manufacture it is possible to build in various modifications to the standard format. These include:

Recesses

Equipment Recess

The standard size is 1.0m long x 0.8m wide x 1.1m deep, however, other sizes are available with length increments of 500mm up to a maximum of 3metres. Fitted with Unistrut for attaching grease reels and other equipment.

Lift Recesses

Full length recess for lights and other service lines.

Tunnels

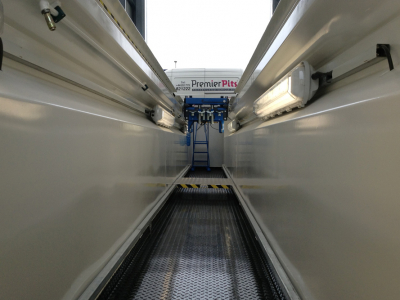

Side Entry and Exit Tunnel

A side exit tunnel is be required for VOSA designated sites with full width steps for entry and exit.

Exit Tunnel

An exit tunnel is required for VOSA designated sites. Vertical exit by ships’ ladder

Connecting Tunnel

Suitable for multiple pit installations and gives ease of access on one level.

Fume Extraction Manifolds

For use with petrol and gas powered vehicles and where there is possible solvent accumulation. It will satisfy possible forthcoming H&S requirements for air movement below finish floor level.

Sumps

Free Standing Brake Tester Sump

Manufactured to suit any equipment – ducts supplied. Also available as a split brake tester pump

Check Wear Unit/Shaker Plate Sump

To suit any make, service ducts supplied. Manual radius plates are also available.

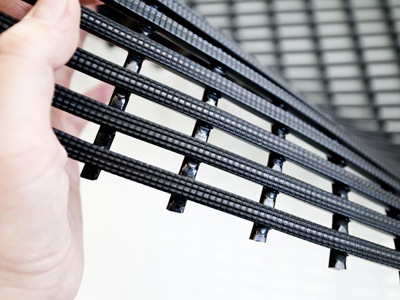

Zone 1 and Zone 2 LED Lights

High quality, long life LED lighting saves up to 50% energy compared to standard pit lights, made of impact-proof polycarbonate with spring clips in acid-proof steel.

Zone 1 – Category 2, 1200mm long.

Zone 2 – Category 3, 1500mm long.

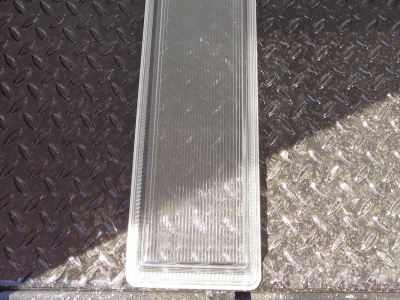

Zone 2

Standard units bought in by Premier Pits, with a polycarbonate body.

Lenses

Replacement lenses available

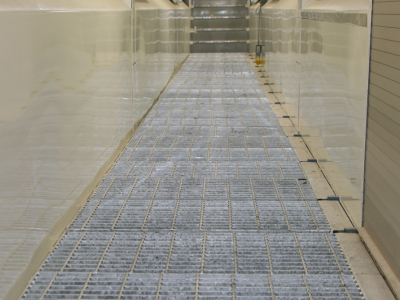

Chequer Plate

Chequer plate is the pit floor standard with conventional floor paint.

Flowforge

Rubber Fatigue Matting