The Project

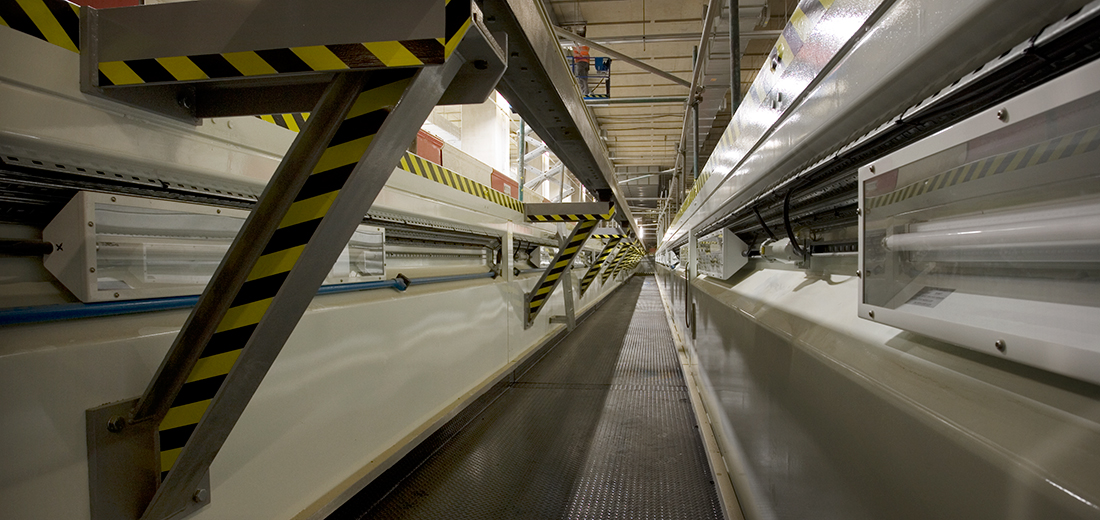

To install prefabricated steel maintenance pits for the passenger transfer system at Heathrow’s Terminal 5.

The Problem

The pits had to be installed 12m below ground level without interfering with other ongoing construction work. Also, the pits had to allow for free access along the length of the pit when in day to day use.

Solution

Due to restricted site access, the pits had to be designed in 8 metre sections prior to manufacture at Premier Pits’ factory in Spalding. They were then delivered by road direct to site. On arrival, the sections were offloaded and lowered by crane in one movement through the terminal roof, into position 12metres below ground level. Here they were bolted together to form 54 metre long water tight pits.

The problem of continuous access was answered by designing supports that only projected halfway across the width of the pits.

Outcome

Both pits were installed within 10 working days during which there was minimum disruption to other construction work. The pits are now operational and are playing a significant part in improving maintenance efficiency and staff working conditions.

Client Details

Client: Balfour Kilpatrick

Location: London Heathrow Terminal 5

Specification

Two 54 metre pits manufactured from pre-formed mild steel, fitted with safety lights and anti-slip flooring with a durable paint finish.